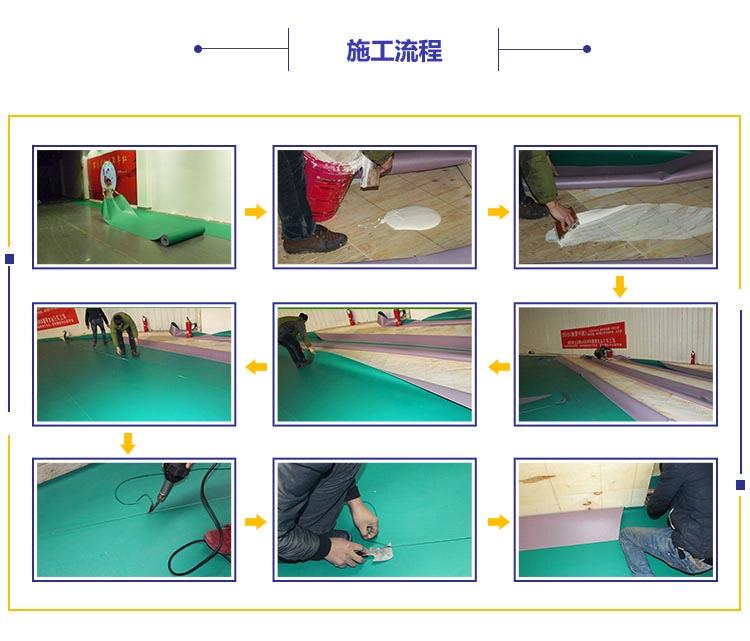

PVC floor construction standard requirements

In order to make a better PVC floor site effect, it is recommended that customers should not blindly ignore the requirements for the ground due to rushing the construction period. High-quality ground materials also require professional PVC floor construction and installation technology to achieve perfect results. The following Yichen small The editor will explain to you the construction standards and requirements of PVC floor:

1. To make a good site, you can't be in a hurry. The ground must be flat, dry, and free of cracks. If self-leveling is done, it must be dry before entering the site for construction.

Second, how to identify whether the self-leveling is dry: you can take a piece of plastic cloth and spread it on it. If there are water droplets on the plastic cloth the next day, it means that it is not completely dry.

3. Try to spread out 24 hours in advance before paving, so that the board has a process of stretching, and the effect of paving will be better.

Fourth, the market said that double-sided welding is actually very unprofessional, and it is purely to deceive customers, and the amount of exercise will inevitably crack. If it is a fixed type, it should be constructed with glue. The most professional mobile type should use imported glue and glass fiber mesh connecting tape, and it will not break when it is rolled up (such as single-sided glue for mobile type, it will break after a few rolls). ).

In short, I hope that customers can use high-quality materials, coupled with professional construction, so as to achieve the best results without any worries.